Thermoforming doesn’t stop at shaping plastic. For many applications, true value is delivered when multiple formed components are assembled into a single, ready-to-install product.

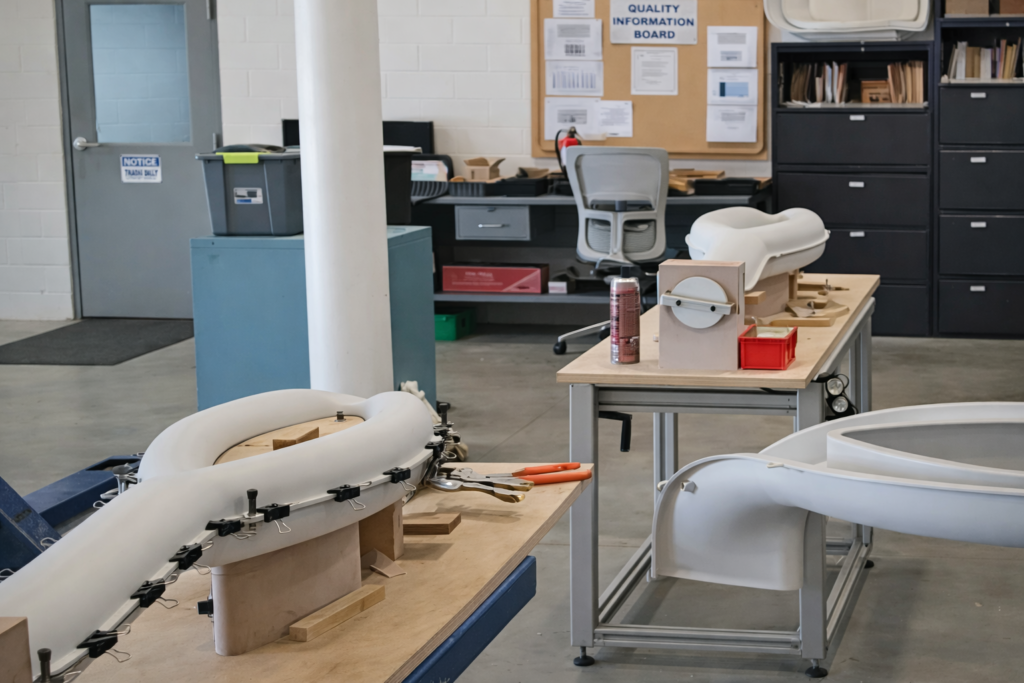

At Om Raj Tech, we partner with Formed Solutions Inc to provide integrated sub-assembly capabilities alongside thermoforming and 5-axis CNC trimming—all manufactured in Michigan, USA.

This allows customers to reduce internal labor, simplify supply chains, and receive fully assembled thermoformed components instead of managing multiple vendors.