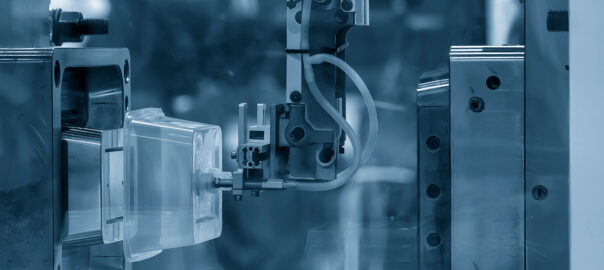

The Midwest is home to many leading injection molding companies that provide high-quality, large-scale production services across a variety of industries, including automotive, medical, and consumer goods. Here is a list of the top 5 injection molders in the Midwest, with Jimdi Plastics proudly representing Michigan. Each of these companies offers advanced manufacturing capabilities and a strong track record of success.

1. Nicolet Plastics

Location: Mountain, WI

Key Benefits:

-

Specializes in highly complex, low-to-medium volume injection molding.

-

Known for their ability to handle intricate designs and tight tolerances, perfect for industries like electronics and medical devices.

-

Offers in-house tooling, design support, and over-molding capabilities to ensure complete project management.

Pros:

-

Expertise in complex part designs and tight tolerances.

-

Offers custom solutions with a high degree of precision.

-

In-house tooling and prototyping capabilities.

Cons:

-

Primarily focuses on low-to-medium volumes, so might not be ideal for extremely high-volume projects.

2. Jimdi Plastics (Represented by Om Raj Tech)

Location: Allendale, MI

Key Benefits:

-

Specializes in custom injection molding for small-to-mid and high-volume production runs.

-

ISO 9001 certified, ensuring high standards for quality control across all stages of production.

-

Serves industries such as automotive, consumer products, and electronics.

-

Known for personalized service, competitive pricing, and flexible production schedules to meet specific client needs.

Pros:

-

ISO-certified for quality assurance.

-

Flexible, catering to both custom and full production runs.

-

Strong focus on customer service and collaboration with clients.

Cons:

-

Focus on custom solutions may sometimes require longer lead times, but this ensures higher quality and precision.

Contact Us:

For more information on how Jimdi Plastics, represented by Om Raj Tech, can help with your injection molding needs, contact us today for custom solutions.

3. Pioneer Plastics

Location: Dixon, KY

Key Benefits:

-

Specializes in high-volume injection molding for a variety of industries, including consumer goods, packaging, and industrial applications.

-

Offers in-house tooling, design, and assembly services, ensuring a streamlined production process.

-

Known for their ability to scale up production quickly, making them ideal for businesses needing large quantities in a short time frame.

Pros:

-

Strong focus on high-volume production.

-

In-house tooling and design services simplify project management.

-

Extensive experience in consumer goods and industrial applications.

Cons:

-

Primarily serves high-volume needs, which may not be ideal for low-volume or highly custom orders.

4. Innovative Plastics

Location: Saint Louis, MO

Key Benefits:

-

Offers custom injection molding with a focus on industrial, automotive, and medical applications.

-

Provides advanced capabilities such as over-molding, insert molding, and two-shot molding.

-

Known for their strong project management and the ability to take a product from concept to production with in-house tooling and design services.

Pros:

-

Advanced injection molding capabilities, including two-shot molding and over-molding.

-

Strong expertise in both industrial and medical applications.

-

Full-service project management from design to production.

Cons:

-

May have longer lead times for highly specialized projects due to their full-service approach.

5. Falcon Plastics

Location: Brookings, SD

Key Benefits:

-

Specializes in custom plastic injection molding for industries such as consumer electronics, healthcare, and industrial equipment.

-

Offers cleanroom molding for medical and healthcare applications, ensuring compliance with strict industry standards.

-

Provides comprehensive design and tooling support, allowing them to manage all aspects of product development.

Pros:

-

Extensive expertise in medical and healthcare industries, including cleanroom production.

-

Strong design and tooling support for product development.

-

Versatile experience across several industries.

Cons:

-

Primarily serves industries with stringent quality standards, which may not suit simpler production needs.

Conclusion

The Midwest is home to many top injection molding companies that excel in different industries, from healthcare to consumer goods. Jimdi Plastics, represented by Om Raj Tech, stands out for its flexibility, customer service, and ISO-certified quality control, making it an excellent choice for businesses seeking both custom and full production injection molding solutions. Companies like Nicolet Plastics and Pioneer Plastics offer specialized capabilities for complex parts and high-volume production, respectively, providing a wide range of options for all injection molding needs.

Contact Us:

Reach out to Om Raj Tech by email sumeet@omrajtech-com-666895.hostingersite.com to learn more about how we can support your injection molding projects with Jimdi Plastics.