Selecting the right material for automotive interiors is crucial to crafting a cabin that is not only comfortable and stylish but also durable and safe. The materials chosen directly impact the vehicle’s aesthetics, comfort, safety, and ease of maintenance, making this decision a pivotal part of any automotive design project. Below are the key factors to consider when choosing materials for automotive interiors:

Key Factors to Consider:

-

Comfort and Ergonomics: Prioritize materials that enhance tactile comfort and reduce vibrations for a smoother ride.

-

Durability and Wear Resistance: Opt for materials that can withstand regular use without showing signs of wear and tear.

-

Safety and Flame Retardancy: Ensure materials comply with safety standards and minimize fire risks.

-

Aesthetics and Design: Select colors, textures, and patterns that align with the vehicle’s design language.

-

Cleanability and Maintenance: Choose materials that are easy to clean and maintain, preserving the interior’s appearance.

-

Noise and Vibration Control: Utilize sound-absorbing materials to reduce cabin noise and improve comfort.

-

Sustainability and Environmental Impact: Consider environmentally friendly materials that support sustainability goals.

1. Comfort and Ergonomics

Comfort is a top priority for automotive interiors, as it directly influences the driver and passengers’ experience. The materials should offer a pleasant tactile feel and contribute to a comfortable seating environment. Opt for fabrics that are soft, breathable, and have moisture-wicking properties to enhance comfort during long drives. Additionally, materials that provide good vibration damping, such as specialized foams, can help create a smoother, more enjoyable ride by reducing the impact of road vibrations.

2. Durability and Wear Resistance

Automotive interiors endure significant wear and tear over time, making durability a critical factor. Materials like leather and synthetic leather (such as polyurethane) are popular for their robustness and resistance to scratches, abrasion, and general wear. Textiles with strong construction and stain-resistant finishes also offer excellent durability, ensuring the interior remains intact and visually appealing even with regular use.

3. Safety and Flame Retardancy

Safety is paramount in automotive design, and interior materials must meet stringent flame retardancy standards to protect passengers. Materials should be carefully selected to minimize fire risks and comply with safety regulations. Flame-retardant fabrics, foams, and plastics are commonly used to enhance safety and ensure that the vehicle meets all necessary safety standards.

4. Aesthetics and Design

The visual appeal of the automotive interior is heavily influenced by the materials used. The choice of colors, textures, and patterns should reflect the vehicle’s design language and brand identity. Materials like leather, fabrics, wood veneers, and decorative trims can be combined to create an inviting and visually stunning interior that resonates with the desired aesthetic and appeals to the target market.

5. Cleanability and Maintenance

Automotive interiors are exposed to spills, stains, and dirt, making cleanability an important consideration. Materials that are easy to clean and maintain help preserve the interior’s appearance and hygiene over time. Stain-resistant fabrics, smooth-surfaced plastics, and other easy-to-clean materials reduce the effort required to keep the cabin looking fresh and tidy, which is a significant selling point for many consumers.

6. Noise and Vibration Control

Interior materials play a key role in managing noise and vibrations within the cabin. Sound-absorbing materials, such as acoustic foams, carpets, and specialized fabrics, help reduce road and engine noise, contributing to a quieter and more comfortable driving experience. These materials enhance the cabin’s acoustics, making the interior feel more insulated and serene.

7. Sustainability and Environmental Impact

With growing awareness of environmental issues, the use of sustainable materials in automotive interiors is increasingly important. Selecting materials made from recycled or renewable sources, or those that are recyclable at the end of their lifecycle, supports environmental responsibility. Options like bio-based plastics and eco-friendly textiles not only reduce the vehicle’s environmental footprint but also appeal to environmentally conscious consumers.

Conclusion

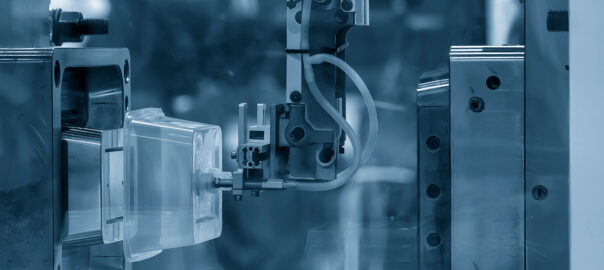

Choosing the right materials for automotive interiors involves injection molding solutions, custom thermoformed plastics, and fiberglass products manufacturers balancing comfort, durability, safety, aesthetics, maintenance, noise control, and sustainability. Each material choice significantly impacts the overall quality and appeal of the vehicle’s interior. By thoroughly evaluating these factors and aligning them with your project’s specific requirements, you can create an automotive interior that not only meets but exceeds expectations in comfort, style, safety, and longevity.