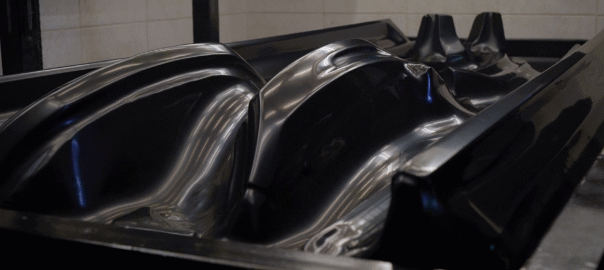

For businesses looking to produce custom thermoformed parts in low volumes or create prototypes before committing to large-scale production, finding the right thermoforming supplier is crucial. Low-volume thermoforming services allow companies to validate designs, explore different material options, and ensure that their products meet specific requirements without the cost and commitment of full-scale production. Here are the top 5 low-volume and prototyping thermoforming suppliers in the USA, offering tailored solutions for your manufacturing needs.

Top 5 Low-Volume and Prototyping Thermoforming Suppliers:

-

Xometry

-

STM Plastics (represented by Om Raj Tech)

-

Protolabs

-

Universal Plastics

-

Allied Plastics

1. Xometry

Overview:

Xometry is a leading on-demand manufacturing platform with a vast network of suppliers. They provide low-volume and prototyping thermoforming services, offering flexible production options for clients across various industries.

Key Benefits:

-

Fast turnaround times for prototypes and small runs.

-

Access to a wide variety of thermoplastics.

-

Nationwide network of vetted manufacturers.

Pros:

-

Extensive material options and fast lead times.

-

Ideal for rapid prototyping and low-volume production.

-

User-friendly online platform for instant quotes.

Cons:

-

Limited customization for highly specialized applications.

2. STM Plastics (Represented by Om Raj Tech)

Overview:

STM Plastics, based in Augusta, Kansas, is known for its specialization in custom low-volume thermoforming services. With a focus on prototyping and short production runs, STM Plastics offers personalized engineering support and tailored solutions to meet specific client needs.

Key Benefits:

-

Dedicated support for small-run thermoforming projects.

-

Experienced in heavy-gauge and thin-gauge thermoforming.

-

Emphasis on high-quality prototyping.

Pros:

-

Custom design assistance and rapid prototyping capabilities.

-

Excellent customer service with attention to detail.

-

Flexible production capabilities for low-volume orders.

Cons:

-

Smaller operation may limit large-scale production capacity.

Contact Us to get a quick quote on your prototyping need.

3. Protolabs

Overview:

Protolabs is renowned for its digital manufacturing services, offering fast and affordable low-volume thermoforming and prototyping solutions. Their advanced automation helps reduce lead times while maintaining high precision in product design and quality.

Key Benefits:

-

Fast quotes and efficient prototyping services.

-

Advanced thermoplastic material options.

-

Emphasis on digital and automated production processes.

Pros:

-

Speedy prototyping services with short lead times.

-

Suitable for clients needing precise, small-batch thermoformed parts.

-

Wide array of material choices.

Cons:

-

Higher costs for highly customized projects.

4. Universal Plastics

Overview:

With decades of experience, Universal Plastics offers custom low-volume thermoforming services, focusing on both prototyping and short production runs. They provide solutions for industries such as aerospace, medical, and consumer goods.

Key Benefits:

-

Custom tooling and prototyping services.

-

Expertise in thin-gauge and heavy-gauge thermoforming.

-

A focus on delivering high-quality prototypes for testing and validation.

Pros:

-

Strong experience in complex thermoformed parts.

-

In-house design and engineering support.

-

High attention to detail and quality assurance.

Cons:

-

Lead times may be longer for custom projects compared to smaller, more agile suppliers.

5. Allied Plastics

Overview:

Allied Plastics offers thermoforming services for prototyping and small production runs. Their focus on quality, design flexibility, and customer satisfaction makes them an excellent choice for clients in need of custom low-volume parts.

Key Benefits:

-

Custom design services for small-batch projects.

-

Expertise in prototyping and small production runs.

-

Focus on maintaining cost-effective solutions for clients.

Pros:

-

Strong design flexibility for various industries.

-

Quality assurance with thorough testing protocols.

-

Competitive pricing for low-volume production.

Cons:

-

Less automation compared to larger competitors, which may lead to longer production times.

Conclusion

When selecting a low-volume or prototyping thermoforming supplier, it’s essential to consider factors like turnaround time, material availability, and design flexibility. STM Plastics, represented by Om Raj Tech, stands out for its exceptional customer service and flexible, custom solutions for prototyping and low-volume production. Whether you’re creating prototypes for validation or need small-scale manufacturing, the suppliers listed above offer the expertise and capabilities to bring your designs to life.

For more information about how Om Raj Tech and STM Plastics can support your low-volume thermoforming needs, contact us today!