Composite materials have become essential in the off-highway sector, offering significant benefits such as reduced weight, increased strength, and improved durability. Resin Transfer Molding (RTM) is one of the leading methods for injection molding manufacturing composite components, but it is not the only option. This article provides a comparative analysis of RTM against other composite manufacturing techniques, such as vacuum infusion, hand lay-up, and autoclave molding, focusing on their respective advantages, challenges, and suitability for off-highway applications.

Resin Transfer Molding (RTM): Overview and Advantages

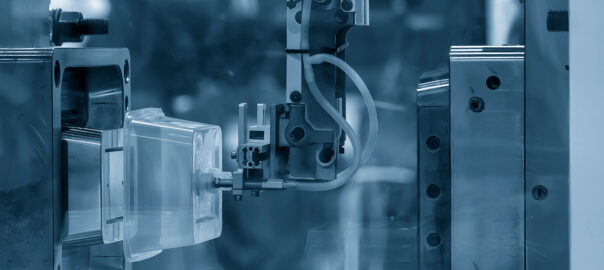

Resin Transfer Molding (RTM) is a closed-mold process that involves injecting molding resin into a mold containing a pre-formed fiber reinforcement. The process is well-known for producing high-quality, complex parts with excellent surface finishes. RTM offers several key advantages, particularly for off-highway applications:

-

Precision and Repeatability: RTM allows for precise control over resin flow and fiber placement, resulting in highly consistent and repeatable parts. This precision is crucial for off-highway components that must meet stringent performance standards.

-

Complex Geometry: RTM can produce parts with complex shapes and integrated features, making it ideal for manufacturing intricate components such as vehicle body panels, structural parts, and enclosures.

-

Surface Finish: The closed-mold nature of RTM results in a smooth surface finish on both sides of the part, reducing the need for post-processing and enhancing the aesthetic appeal of visible components.

However, RTM also presents some challenges, including the need for precise mold design and the potential for high tooling costs, especially for low-volume production runs.

Vacuum Infusion: A Flexible Alternative

Vacuum infusion is another closed-mold process, similar to RTM, but with some distinct differences. In vacuum infusion, the resin is drawn into the mold using vacuum pressure, rather than being injected under pressure as in RTM.

-

Lower Tooling Costs: Vacuum infusion typically requires less expensive tooling compared to RTM, making it a more cost-effective option for lower-volume production runs or large parts.

-

Material Flexibility: The vacuum infusion process can accommodate a wide range of fiber types and resin systems, offering flexibility in material selection based on the specific needs of the application.

-

Improved Fiber Wet-Out: The vacuum pressure helps to ensure complete fiber wet-out, which can enhance the mechanical properties of the final part.

However, vacuum infusion may not be as precise as RTM, particularly for parts with very complex geometries. The surface finish is also typically not as smooth as what can be achieved with RTM, which may require additional finishing processes.

Hand Lay-Up: Traditional and Cost-Effective

Hand lay-up is one of the oldest and simplest composite manufacturing techniques. It involves manually placing layers of fiber reinforcement in an open mold and applying resin by hand.

-

Low Capital Investment: Hand lay-up requires minimal equipment and tooling, making it the most cost-effective option for small-scale production and prototyping.

-

Flexibility in Design: The process is highly adaptable, allowing for on-the-fly adjustments to fiber orientation and resin application, which can be beneficial for custom or one-off parts.

However, hand lay-up is labor-intensive and less consistent than automated processes like RTM. The quality of the final part is highly dependent on the skill of the operator, and the process is generally unsuitable for high-volume production due to its slow cycle times.

Autoclave Molding: High-Performance Composites

Autoclave molding is a process used to produce high-performance composite parts, particularly in aerospace and defense applications. The process involves placing a resin-impregnated fiber preform into a mold, which is then cured under heat and pressure in an autoclave.

-

Superior Mechanical Properties: The combination of high pressure and temperature during the autoclave process results in parts with exceptional mechanical properties, including high strength and stiffness.

-

High-Quality Surface Finish: Like RTM, autoclave molding can produce parts with excellent surface finishes, reducing the need for post-processing.

However, autoclave molding is expensive and time-consuming, with high tooling and operational costs. It is typically reserved for applications where performance is the primary concern, and cost is less of an issue.

Suitability for Off-Highway Applications

When selecting a composite injection molding manufacturing process for off-highway applications, several factors must be considered, including cost, production volume, part complexity, and performance requirements.

-

RTM is well-suited for producing high-performance, complex parts in medium to high volumes. Its precision and ability to produce high-quality finishes make it ideal for structural components, body panels, and enclosures in off-highway vehicles.

-

Vacuum Infusion offers a balance between cost and performance, making it a good choice injection molding for larger parts or lower-volume production runs where material flexibility is important.

-

Hand Lay-Up is best suited for prototyping, custom parts, or small-scale production, where cost is a major concern, and performance requirements are less stringent.

-

Autoclave Molding is the go-to process for high-performance parts that must meet the most demanding mechanical and environmental conditions, though it is generally not cost-effective for high-volume production in the off-highway sector.

Conclusion

Choosing the right composite manufacturing process is crucial for optimizing the performance, cost, and production efficiency of off-highway vehicle components. While RTM offers several advantages, particularly for complex and high-performance parts, other methods like vacuum infusion, hand lay-up, and autoclave injection molding each have their own strengths and are better suited to specific applications. By understanding the benefits and limitations of each technique, plastic manufacturers can make informed decisions that align with their production goals and the specific needs of the off-highway injection molding industry.