Pressure thermoforming is the ideal plastic pressure forming process when aesthetics, surface detail, and precision matter. With 8 thermoforming presses: 5 of which are pressure forming capable, we help customers achieve sharp, crisp, injection-mold-like parts without the high tooling cost of injection molding.

At Om Raj Tech, we represent Formed Solutions Inc, where all pressure thermoformed parts are manufactured in Michigan, USA. If you’re searching for pressure thermoforming near you or Made in USA thermoforming, this capability is built specifically for high-expectation applications.

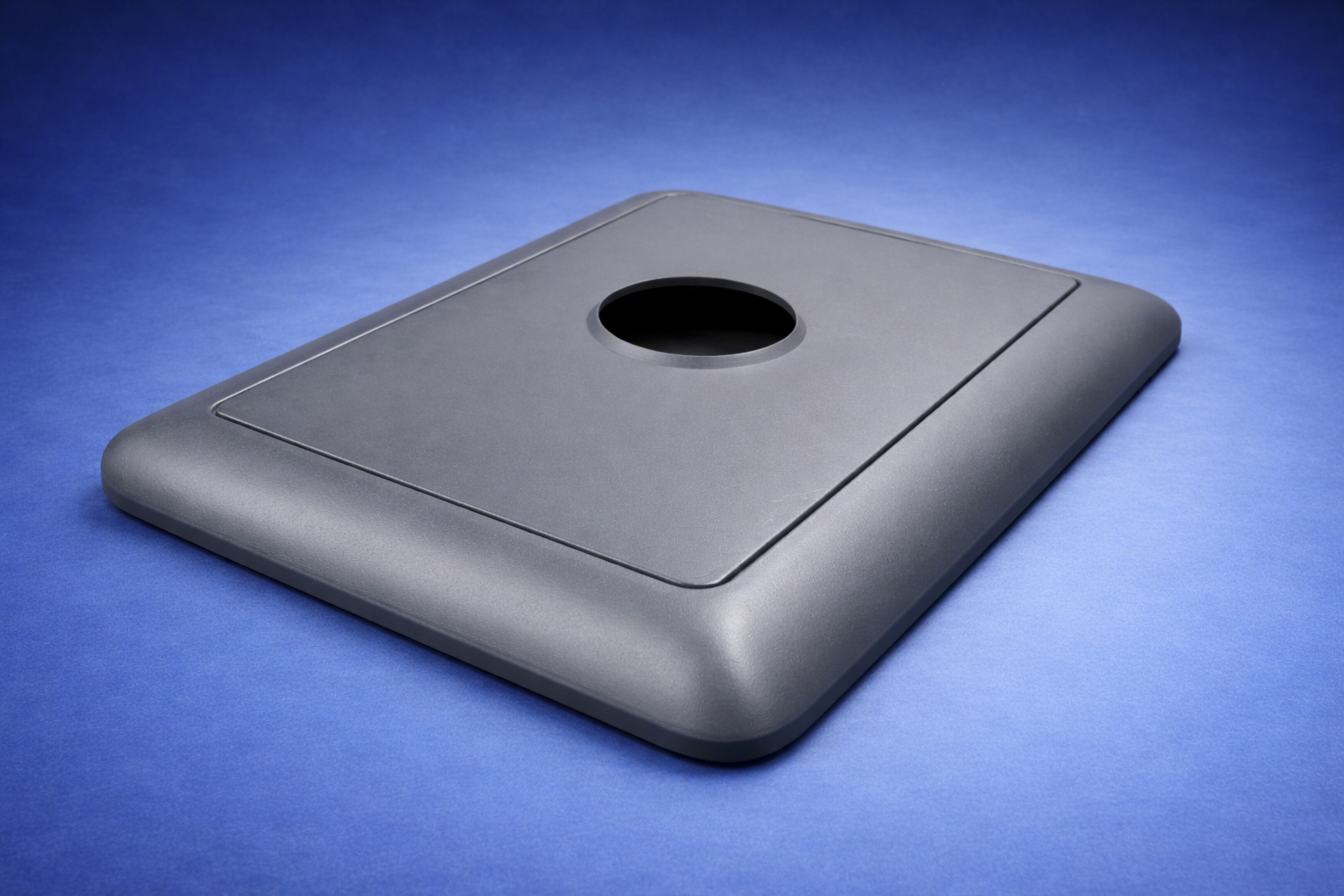

Pressure thermoforming combines vacuum forming with positive air pressure to force heated plastic sheets into temperature-controlled aluminum molds. Unlike standard vacuum forming, pressure forming allows us to capture fine textures, tight radii, and sharp corners, producing parts that closely resemble injection-molded components.

Key process highlights:

Tooling built to the A-side of the part (typically female aluminum molds)

Vacuum pulls the sheet into the cavity

Positive air pressure up to 80 PSI pushes plastic into fine details

Mold textures can be acid-etched for consistent cosmetic finishes

Supports wall thicknesses from thin gauge up to ~6 mm

This video walks through a real pressure-formed enclosure, showing both left-hand and right-hand components and explaining how pressure forming delivers superior aesthetics.

In the video, you’ll see:

How heated plastic exits the oven and enters the forming station

The mold pulling vacuum to draw plastic into the cavity

A pressure box sealing and applying up to 80 PSI of air pressure

The difference between the A-side (tool-contact side) and B-side (air-pressure side)

Why pressure forming is preferred for medical enclosures, dash panels, and cosmetic housings

This pressure thermoforming process is commonly selected when customers need parts that look injection molded but don’t justify injection tooling.

Our pressure thermoforming capability is not just about forming plastic—it’s about delivering finished, ready-to-assemble components.

Advanced Tooling & Process Control

Secondary Assembly & Value-Added Operations

We go beyond forming by offering:

This allows customers to receive functional, production-ready parts, not just formed shells

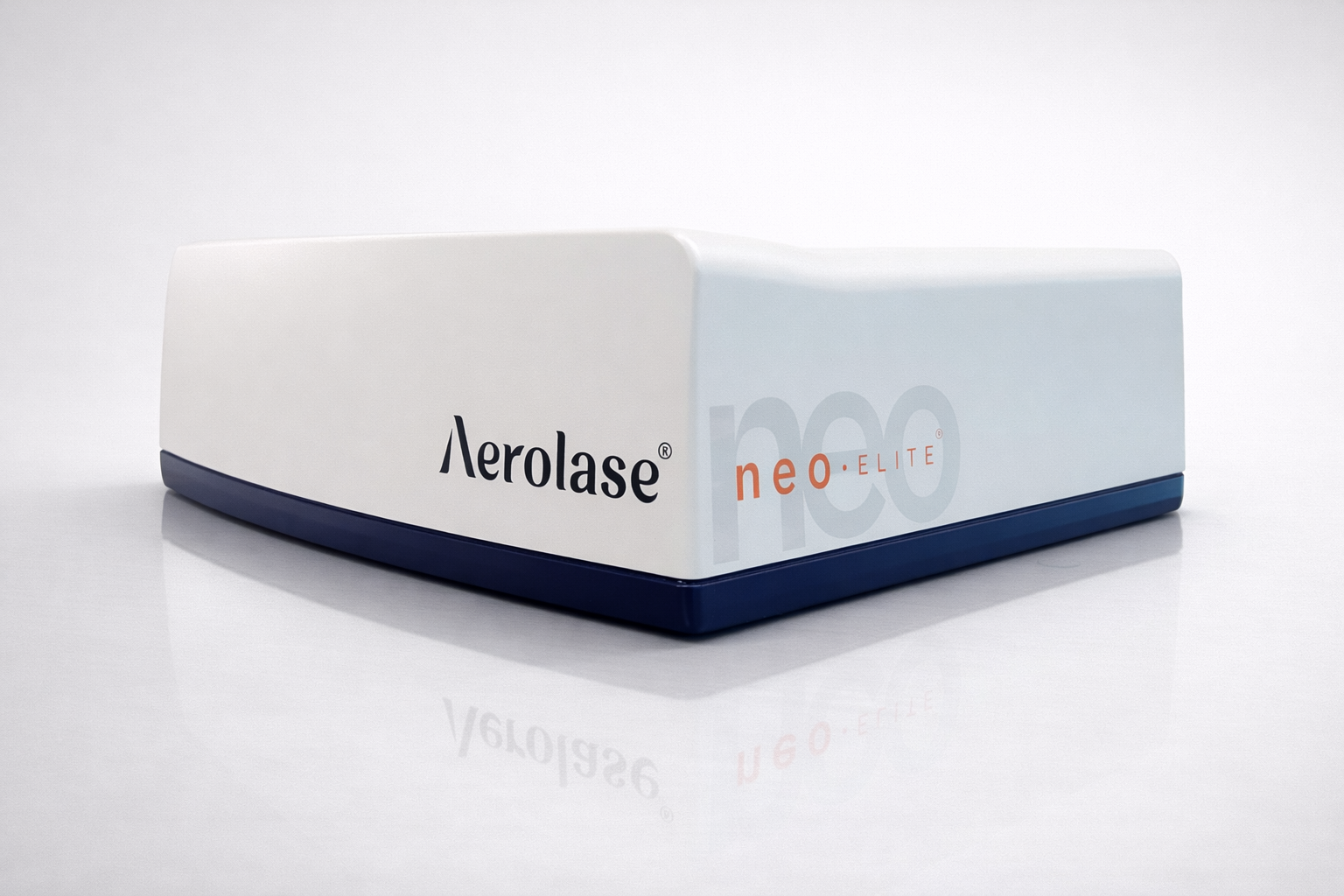

Pressure thermoforming is commonly used in applications that demand high aesthetics and performance, including:

Medical enclosures & housings

Automotive interior components & dash panels

Furniture and office equipment housings

Polycarbonate covers and flares

Prototypes and low-to-medium volume cosmetic parts

If your product requires clean textures, crisp edges, and premium appearance, pressure thermoforming is often the best fit.

Injection-mold-like appearance at lower tooling cost

Excellent for low-to-medium production volumes

Supports thicker gauge materials and tight radii

Faster tooling lead times than injection molding

Made in USA manufacturing in Holland, Michigan

If you’re searching for a pressure thermoforming manufacturer, pressure forming plastic near me, or a Made in USA thermoforming partner, Om Raj Tech offer the experience, capacity, and finishing capabilities to support your program from prototype to production.