Thermoformed plastic packaging trays are a practical, customizable, and cost-effective solution for protecting and organizing precision machined parts. Industries such as automotive, aerospace, electronics, and medical devices rely on these trays to keep delicate components safe during transit and storage. With thermoforming, companies can design tailored trays that ensure precision parts are protected, organized, and easily handled, all while benefiting from cost-efficiency compared to other packaging methods.

In this blog, you will learn:

-

Examples of Precision Machined Parts That Benefit from Thermoformed Trays – How industries like automotive, aerospace, and medical devices use thermoformed trays.

-

Types of Thermoforming Processes – The differences between vacuum forming, pressure forming, and twin-sheet thermoforming, and when to use each.

-

Key Design Considerations for Thermoformed Trays – Factors like part geometry, material selection, and stackability that influence tray design.

-

Material Options for Thermoformed Packaging Trays – Common plastics used in thermoforming and how they enhance the tray’s durability and protection.

-

Cost Benefits of Thermoformed Trays Compared to Other Packaging Solutions – A breakdown of why thermoformed trays are a more economical choice over injection molding, foam, or metal packaging.

-

Industry References and Supporting Research – Reliable sources and research articles to deepen your understanding of thermoforming and its applications.

Precision Machined Parts That Benefit from Thermoformed Trays

Precision machined parts are critical in industries where accuracy, tolerance, and quality are paramount. These parts often have intricate geometries and delicate finishes, making them vulnerable to damage if not packaged properly. Thermoformed trays ensure that each part is securely placed, minimizing movement and protecting against environmental factors. Here are some examples of machined parts commonly packaged using thermoformed trays:

-

Automotive Industry: Components like engine parts, gears, and precision-cut fasteners require custom-fit trays that prevent scratches and misalignment during transportation. High-value parts, such as transmission gears or custom brake components, need individualized pockets to ensure each part stays secure.

-

Aerospace Industry: In aerospace, thermoformed trays are used to package precision components such as turbine blades, aerospace fasteners, and connectors. Due to the high value and tight tolerances of these parts, thermoformed trays are ideal for ensuring damage-free transport. Thermoforming solutions with anti-static materials may also be needed to protect sensitive electronic parts.

-

Medical Devices: Thermoformed trays are also widely used for medical devices such as surgical instruments, implants, and diagnostic tools. These trays not only protect the physical components but can also be designed to maintain a sterile environment, meeting the regulatory requirements of the medical industry.

-

Electronics Industry: For electronics manufacturers, thermoformed trays can prevent damage to sensitive components like printed circuit boards (PCBs), connectors, and electronic housings. Anti-static trays are often used to safeguard against electrostatic discharge (ESD).

Types of Thermoforming for Packaging Trays

Thermoforming is a process in which plastic sheets are heated and molded into desired shapes using various methods. The two most common thermoforming methods for packaging trays are vacuum forming and pressure forming.

Vacuum Forming:

-

Process: In vacuum forming, a heated plastic sheet is stretched over a mold, and a vacuum is applied to suck the sheet tightly against the mold. This method is ideal for creating simpler trays with shallow designs.

-

Best Used For: Vacuum forming is best for packaging trays that don’t require extremely detailed designs but need to securely hold components such as automotive fasteners or medical tools.

-

Cost Benefits: Vacuum forming is less expensive than pressure forming, making it ideal for businesses that need to produce large quantities of trays without complex detailing. The lower tooling costs also make it a preferred option for small-to-medium volume production runs.

Pressure Forming:

-

Process: Pressure forming uses additional pressure alongside the vacuum to press the heated plastic sheet against the mold, creating more detailed and precise trays. This process allows for sharper features and higher levels of customization.

-

Best Used For: Pressure forming is used when detailed features are needed in the tray design. Industries like aerospace and electronics, where precision parts must be perfectly cradled, often utilize pressure-formed trays.

-

Cost Benefits: Although slightly more expensive than vacuum forming, pressure forming allows for better precision and higher-quality finishes, making it suitable for higher-end parts.

Twin-Sheet Thermoforming:

-

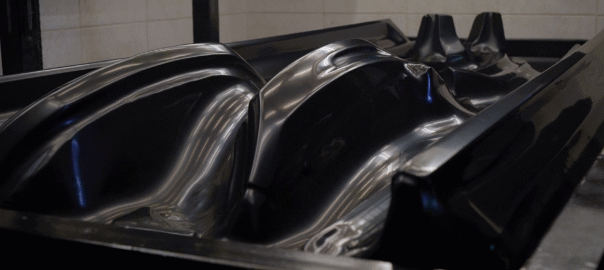

Process: Twin-sheet thermoforming heats two plastic sheets simultaneously and molds them together, creating hollow, durable structures. It’s commonly used for large, heavy-duty trays.

-

Best Used For: Large or heavy components that require additional protection, such as automotive body parts or large aerospace components, benefit from the rigidity and durability of twin-sheet thermoforming.

Material Considerations

The material chosen for thermoformed trays can greatly impact their functionality and durability. Some common materials include:

-

Polyethylene (PE): Known for impact resistance and durability, PE is ideal for heavy-duty automotive or industrial components.

-

Polyvinyl Chloride (PVC): Offers excellent clarity and chemical resistance, making it suitable for medical and electronics trays.

-

Acrylonitrile Butadiene Styrene (ABS): Used for trays that require higher strength and rigidity, ABS is often utilized for aerospace components.

-

Anti-Static Plastics: Critical for electronic components, anti-static trays protect sensitive parts from electrostatic discharge.

Selecting the right material depends on the industry and specific application, but all materials contribute to the tray’s ability to protect high-value parts during transit and storage.

Cost Benefits of Thermoformed Trays Compared to Other Packaging Methods

Thermoformed trays offer several cost advantages over other types of packaging, such as injection-molded trays, foam inserts, or metal containers:

-

Lower Tooling Costs: Thermoforming requires significantly lower tooling costs than injection molding. This makes it ideal for businesses that need custom trays but don’t want to invest in expensive molds for small-to-medium production runs.

-

Material Efficiency: Thermoformed trays are lightweight yet strong, reducing both material usage and shipping costs. This can be particularly beneficial in industries like aerospace, where weight is a crucial consideration.

-

Customization: The flexibility of the thermoforming process allows for high levels of customization at a fraction of the cost of other methods. This means businesses can create highly specific trays that perfectly fit their components without the need for expensive multi-part assemblies.

-

Reusable and Recyclable: Many thermoformed trays are designed for multiple uses, making them a cost-effective option for businesses that need to store or transport parts multiple times. Additionally, thermoformed plastics are often recyclable, contributing to environmental sustainability efforts.

Further Reading and References

-

Society of Plastics Engineers (SPE) – SPE publishes research on thermoforming processes and packaging innovations, providing insights into material selection and process optimization.

Source: 4spe.org -

Thermoforming Quarterly – Published by the Thermoforming Division of SPE, this journal provides research on new developments in thermoforming technology, including applications for packaging trays.

Source: Thermoforming Quarterly -

Plastics Industry Association (PLASTICS) – Reports on packaging trends and plastic thermoforming processes, offering valuable insights into industry best practices.

Source: plasticsindustry.org -

Packaging Digest – Articles like “The Advantages of Thermoforming Plastic Packaging” discuss the benefits of thermoformed packaging in terms of cost, flexibility, and sustainability, especially for industries like automotive and electronics.

Source: packagingdigest.com -

Plastics Technology – Offers in-depth industry articles on thermoforming processes, materials, and packaging applications, making it a great resource for exploring the cost and design benefits of thermoformed packaging trays.

Source: plasticstoday.com

Conclusion

Thermoformed plastic trays provide a highly versatile and cost-effective solution for packaging precision machined parts. With lower tooling costs, customizable designs, and the ability to protect sensitive components, thermoformed trays are ideal for industries such as automotive, aerospace, medical, and electronics.

At Om Raj Tech, we partner with STM Plastics to deliver custom-designed thermoformed trays that meet your specific needs. With years of experience and expertise in creating packaging trays for a variety of industries, we ensure that your precision parts are well-protected and cost-effectively packaged.

Contact us today to learn how STM Plastics, represented by Om Raj Tech, can help you design and produce high-quality thermoformed trays for your precision machined parts