In today’s competitive manufacturing landscape, having a well-thought-out sourcing strategy for plastic injection molding is crucial. This comprehensive guide will walk you through the key steps to develop an effective sourcing strategy that ensures quality, cost-efficiency, and reliability in your supply chain.

1. Understand Your Requirements

Before diving into sourcing, it’s essential to have a clear understanding of your project requirements:

-

Material specifications: Consider not just the polymer type (e.g., ABS, PP, PC), but also specific grades, additives, and color requirements.

-

Production volume: Define your annual volume needs and potential seasonal fluctuations.

-

Quality standards: Specify tolerances, surface finish requirements, and any industry-specific certifications (e.g., FDA, UL, RoHS).

-

Delivery timelines: Outline your lead time expectations and any just-in-time (JIT) delivery needs.

-

Budget constraints: Determine your target piece price and consider total cost of ownership.

Example: A medical device manufacturer requiring high-precision ABS parts with biocompatibility certifications and strict quality control measures.

2. Identify Potential Suppliers

Cast a wide net to find potential suppliers:

-

Attend industry trade shows: Visit events like NPE (National Plastics Exposition) or regional plastics industry shows.

-

Utilize online directories: Explore platforms like ThomasNet or GlobalSpec.

-

Seek recommendations from industry peers: Leverage your network in manufacturing associations.

-

Consider both domestic and international options: Weigh the pros and cons of nearshore vs. offshore sourcing.

Pro tip: Create a scorecard to systematically evaluate potential suppliers based on your key criteria.

3. Evaluate Supplier Capabilities

When assessing potential suppliers, consider:

-

Technical expertise and experience: Look for suppliers with experience in your specific industry or similar applications.

-

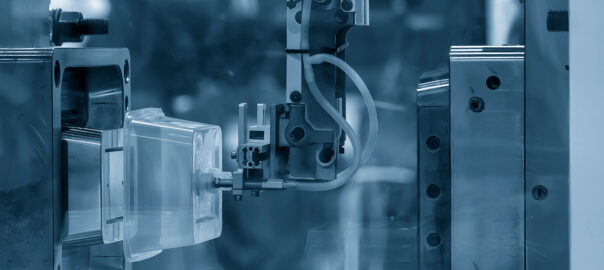

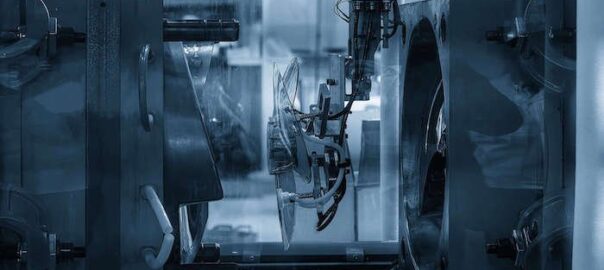

Equipment and capacity: Assess their machine tonnage range, multi-cavity capabilities, and automation level.

-

Quality control processes: Inquire about in-process quality checks, SPC implementation, and metrology equipment.

-

Certifications: Verify relevant certifications like ISO 9001, IATF 16949 for automotive, or ISO 13485 for medical devices.

-

Financial stability: Request financial references or credit reports to ensure long-term viability.

Pro Tip: A supplier with expertise in optical-grade polycarbonate molding might be ideal for a lighting manufacturer, even if they’re not the lowest-cost option.

4. Request for Quotation (RFQ)

Develop a comprehensive RFQ that includes:

-

Detailed part specifications: Provide 3D CAD files, 2D drawings with GD&T callouts, and material specifications.

-

Production volumes: Include current needs and projected growth over 3-5 years.

-

Quality requirements: Specify critical-to-quality (CTQ) characteristics and acceptable quality levels (AQL).

-

Delivery expectations: Outline your inventory management strategy (e.g., kanban, consignment inventory).

-

Pricing structure preferences: Request tiered pricing for different volume levels and potential value-added services.

Best practice: Include a non-disclosure agreement (NDA) to protect your intellectual property when sharing designs.

5. Conduct Site Visits

For shortlisted suppliers, arrange site visits to:

-

Assess facility conditions: Evaluate cleanliness, organization, and adherence to lean manufacturing principles.

-

Evaluate production processes: Observe setups, cycle times, and material handling procedures.

-

Meet the team: Engage with engineering, quality, and production staff to gauge expertise and culture fit.

-

Verify capabilities firsthand: Confirm the presence and condition of equipment listed in supplier responses.

Pro tip: Pay attention to how the supplier handles current customer projects to gain insights into their operational practices.

6. Negotiate Terms

Once you’ve identified preferred suppliers:

-

Discuss pricing structures: Negotiate volume-based discounts, consider long-term agreements for price stability.

-

Establish delivery terms: Define on-time delivery metrics and any penalties for non-compliance.

-

Agree on quality assurance processes: Establish incoming inspection protocols, corrective action procedures, and continuous improvement expectations.

-

Define communication protocols: Set up regular performance reviews and escalation procedures for issues.

Example: Implement a supplier scorecard that tracks key performance indicators (KPIs) like quality, delivery, responsiveness, and cost.

7. Implement a Dual-Sourcing Strategy

Consider maintaining relationships with multiple suppliers to:

-

Mitigate supply chain risks: Have backup options in case of disruptions (e.g., natural disasters, financial instability).

-

Encourage competitive pricing: Use benchmark pricing to negotiate better terms.

-

Ensure production flexibility: Balance workload across suppliers to manage capacity constraints.

Strategy: Aim for an 80/20 split between primary and secondary suppliers to maintain leverage while fostering strong partnerships.

8. Continuous Improvement

Regularly review and optimize your sourcing strategy:

-

Monitor supplier performance: Conduct quarterly business reviews to discuss KPIs and improvement opportunities.

-

Stay informed about market trends: Keep abreast of new materials, technologies, and industry regulations that could impact your sourcing strategy.

-

Seek opportunities for cost reduction and quality improvement: Collaborate with suppliers on design for manufacturability (DFM) initiatives, material substitutions, or process optimizations.

9. Embrace Technology and Innovation

Leverage technology to enhance your sourcing strategy:

-

Implement digital procurement tools: Use e-sourcing platforms for more efficient RFQ processes and supplier management.

-

Explore additive manufacturing: Consider 3D printing for rapid prototyping or low-volume production to complement injection molding.

-

Investigate Industry 4.0 technologies: Partner with suppliers who are adopting smart manufacturing practices, such as IoT-enabled machines for real-time production monitoring.

Future trend: Keep an eye on emerging technologies like artificial intelligence for predictive quality control and blockchain for supply chain transparency.

10. Innovative Approaches to Supplier Sourcing and Management

To stay ahead in the competitive world of plastic injection molding, consider these unique insights and perspectives:

a) Collaborative Innovation Partnerships

Instead of traditional supplier-customer relationships, consider forming innovation partnerships:

-

Co-invest in new technologies: Partner with suppliers to jointly invest in advanced injection molding technologies, sharing both the risks and rewards.

-

Open-book costing: Implement transparent costing models to identify mutual cost-saving opportunities and fairly distribute benefits.

-

Shared IP development: Collaborate on developing proprietary processes or materials, with clear agreements on IP ownership and licensing.

Example: An automotive parts manufacturer partnered with their injection molder to develop a proprietary light-weighting technique, resulting in a 20% weight reduction and improved fuel efficiency for their client’s vehicles.

b) Vertical Integration Assessment

Regularly evaluate the benefits of vertical integration versus outsourcing:

-

Conduct make-vs-buy analyses: Periodically reassess whether to bring certain injection molding processes in-house or continue outsourcing.

-

Partial integration: Consider hybrid models where you own the molds but outsource the molding process, or vice versa.

-

Supplier incubation: Invest in promising suppliers to help them grow and align more closely with your needs.

Example: A consumer electronics company invested in their own injection molding equipment for high-volume, core components while outsourcing lower-volume, specialized parts.

c) Geographical Diversification

Think beyond traditional sourcing locations:

-

Emerging markets: Explore up-and-coming manufacturing hubs like Vietnam or Eastern Europe for injection molding capabilities.

-

Reshoring opportunities: Evaluate the total cost of ownership for bringing production closer to your main markets.

-

Distributed manufacturing: Consider a network of smaller, localized suppliers instead of relying on a few large, centralized ones.

Insight: Some companies are creating “manufacturing clusters” where they co-locate with key suppliers to reduce logistics costs and improve collaboration.

d) Sustainability-Driven Sourcing

Incorporate sustainability into your sourcing decisions:

-

Circular economy partners: Prioritize suppliers who offer recycling programs or use recycled materials in their injection molding processes.

-

Carbon footprint analysis: Include carbon emissions in your supplier evaluation criteria, considering both production and transportation.

-

Bio-based materials: Partner with suppliers experienced in molding bio-based or biodegradable plastics.

Trend: Some innovative companies are partnering with oceanographic institutions to source ocean-bound plastics for their injection molded products, creating a positive environmental impact.

e) Digital Twin Supplier Integration

Leverage advanced digital technologies:

-

Virtual factory tours: Use VR/AR technologies to conduct remote supplier audits and process verifications.

-

Real-time production monitoring: Integrate your ERP system with your suppliers’ MES (Manufacturing Execution Systems) for live updates on production status.

-

Predictive quality assurance: Utilize machine learning algorithms to predict potential quality issues based on real-time molding parameters shared by suppliers.

Future perspective: As digital twin technology advances, you might be able to run virtual simulations of your entire supply chain, optimizing supplier selection and production allocation in real time.

By incorporating these innovative approaches into your sourcing strategy, you can create a more resilient, efficient, and forward-thinking supply chain for your plastic injection molding needs.