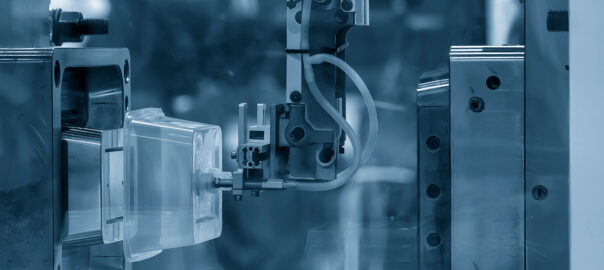

Injection molding is a key manufacturing process for creating plastic parts at high volumes with precision. However, if you’re seeing a surge in product returns, it’s likely due to technical issues that need addressing. Product returns not only affect profit margins but can also erode customer trust. In this article, we’ll delve into the common reasons for injection molded part returns and offer technical solutions to improve part quality and reduce defects, ultimately helping you decide whether a change of supplier is necessary.

1. Common Issues Leading to Injection Molded Part Returns

Several factors can lead to the production of defective injection molded parts, but the primary causes of product returns typically involve dimensional inaccuracies, surface defects, and material-related problems. Understanding these issues can help manufacturers diagnose root causes and make necessary adjustments to reduce defects.

1.1. Dimensional Inaccuracy

Dimensional inaccuracies in injection molded parts occur when parts deviate from the specified dimensions and tolerances. These deviations can cause improper fit or functionality, leading to returns. Common causes include:

-

Improper Tool Design: If the mold isn’t designed to account for shrinkage and cooling, the final part may not match the intended dimensions.

-

Material Flow Issues: Uneven flow of the molten plastic through the mold can lead to variations in part thickness, warping, and other dimensional discrepancies.

Solution: Implement a robust Mold Flow Analysis. Using software like Autodesk Moldflow, engineers can simulate the flow of molten plastic through the mold cavity. This allows them to identify potential issues such as uneven cooling or insufficient filling, and correct these before production begins. Ensure that shrinkage compensation is included in the mold design to account for material properties.

1.2. Surface Defects

Surface defects, such as weld lines, sink marks, or excessive flash, are major contributors to part rejections. Surface appearance is crucial, particularly for consumer-facing products where aesthetics are important, or for functional parts where defects could compromise performance.

-

Weld Lines: These occur when two flow fronts meet and fail to fuse properly, often weakening the part at the point of the weld.

-

Sink Marks: Often caused by uneven cooling, sink marks result in depressions on the surface of the part. These can occur in thicker sections of the part where the internal material cools and contracts at a different rate than the surface.

-

Excessive Flash: Flash occurs when molten plastic escapes the mold cavity and solidifies outside of the intended part design. This is usually due to insufficient clamping force or worn molds.

Solution: To reduce surface defects, suppliers should use vision inspection systems integrated with automated production lines to identify defects early in the process. Mold maintenance is also essential; a comprehensive tool management program ensures that mold surfaces are polished and checked for wear, preventing flash and weld line issues. Hot runner systems can also be used to prevent the formation of weld lines by controlling the flow of plastic and maintaining a consistent temperature across the mold.

1.3. Material Defects

Material selection and handling are critical factors in determining part quality. Defects such as warping, brittleness, and contamination can occur due to improper material selection, poor drying processes, or incorrect processing temperatures.

-

Improper Material Selection: Choosing a material that doesn’t match the performance requirements of the part can lead to premature failure. For example, selecting a resin with poor temperature resistance for a part used in high-heat environments can cause deformation.

-

Material Contamination: Contaminants such as moisture or dust can affect the integrity of the plastic, leading to voids or inconsistent mechanical properties.

-

Incorrect Drying or Processing: Resins must be properly dried before molding to prevent moisture-related defects, such as bubbles or voids, which can weaken the part.

Solution: Engineers must ensure proper material selection based on performance requirements such as strength, flexibility, and temperature tolerance. Suppliers should use automated material dryers to maintain optimal moisture levels, preventing contamination and processing defects. Additionally, regular monitoring of processing parameters such as temperature and pressure ensures consistent material behavior during molding.

2. Technical Solutions for Reducing Injection Molded Part Defects

While identifying the root causes of defects is important, implementing technical solutions that address these issues is key to improving product quality and reducing return rates. Below are some advanced strategies that can be implemented to enhance the injection molding process:

2.1. Mold Flow Analysis and Simulation

Using mold flow analysis tools like Autodesk Moldflow allows engineers to simulate the entire injection molding process before production begins. This simulation helps optimize mold design, gate location, cooling time, and material flow to minimize potential defects.

-

Gate Location Optimization: Proper gate placement ensures even flow of molten plastic through the mold. Poor gate locations can lead to uneven filling, weld lines, and flow marks, resulting in part defects.

-

Cooling Time Optimization: Cooling times must be accurately calculated to avoid issues such as warping, shrinkage, or sink marks. Simulations help identify where cooling channels should be placed in the mold to ensure even cooling.

By conducting detailed simulations, manufacturers can fine-tune mold designs and predict potential issues, saving time and money during actual production.

2.2. Tooling and Mold Maintenance

Molds are at the core of the injection molding process, and their condition has a direct impact on the quality of the parts produced. Proper maintenance of injection molding tools can extend their life and prevent issues such as flashing, dimensional inconsistencies, and surface defects.

-

Preventive Maintenance Programs: Implement regular preventive maintenance schedules to clean, lubricate, and inspect molds for wear and tear. This prevents defects caused by deteriorating molds, such as poor surface finish or misalignment.

-

Tool Management Software: Suppliers should use tool management software to monitor mold usage and track necessary repairs, ensuring that molds are maintained efficiently and replaced when necessary.

2.3. Advanced Process Control

Maintaining consistency in injection molding requires tight control over critical parameters such as temperature, pressure, and injection speed. Modern injection molding machines equipped with PLC (Programmable Logic Controllers) and SCADA (Supervisory Control and Data Acquisition) systems allow for real-time monitoring and adjustment of these variables to ensure that the molding process remains consistent.

-

Real-Time Monitoring: By using real-time data monitoring, engineers can detect any deviations from the optimal process settings, such as pressure drops or temperature fluctuations, and make immediate corrections.

-

Automation Integration: Incorporating robotic part removal systems and automated inspection equipment ensures that every part meets the required specifications before it leaves the production line, reducing manual errors and enhancing consistency.

3. Monitoring Quality and Reducing Returns

Quality control should be a continuous process throughout production, not just at the end. By integrating automated quality control systems and leveraging real-time data, manufacturers can detect and fix issues early, reducing the chance of product returns.

3.1. In-Line Quality Control

In-line inspection systems use cameras and sensors to monitor parts as they are produced, identifying defects such as warping, sink marks, or surface imperfections. By detecting these issues in real time, manufacturers can halt production, adjust parameters, and prevent defective parts from being shipped.

-

Vision Inspection Systems: Automated vision systems use high-resolution cameras to inspect parts for surface defects and dimensional accuracy. These systems can detect even minute flaws and send alerts to operators for immediate correction.

-

Laser Scanning: In some cases, laser scanning technology can be employed to measure dimensional tolerances to a high degree of precision, ensuring that all parts meet exact specifications.

3.2. Real-Time Data Analytics

Collecting and analyzing data from the injection molding process can provide valuable insights into trends and recurring issues. By using data analytics platforms, manufacturers can track key metrics such as defect rates, cycle times, and material consumption, allowing them to identify areas for improvement.

-

Trend Analysis: By reviewing long-term data trends, manufacturers can pinpoint the exact moment when defects start appearing, allowing for proactive maintenance or process adjustments.

-

Predictive Maintenance: Using predictive algorithms, manufacturers can forecast potential equipment failures before they occur, preventing unplanned downtime and ensuring consistent part quality.

Conclusion

Reducing return rates for injection molded parts requires a combination of advanced process control, tooling maintenance, and quality inspection technologies. By addressing the common technical issues such as dimensional inaccuracies, surface defects, and material inconsistencies, manufacturers can significantly reduce defects and ensure that products meet customer expectations.

Om Raj Tech – Your Partner in Injection Molding Quality

At Om Raj Tech, we represent industry-leading injection molding manufacturers equipped with the latest technologies to ensure top-tier quality. Our partners use advanced mold flow simulations, automated inspection systems, and real-time data monitoring to reduce defects and lower return rates. Contact us today to learn how we can help optimize your injection molding process for better quality and efficiency.