The marine industry has long relied on fiberglass for its superior strength, lightweight properties, and resistance to harsh marine environments. Resin Transfer Molding (RTM) has emerged as a preferred manufacturing process for producing high-quality fiberglass components for boats and other marine vessels. This article explores the specific applications of RTM in the marine industry, focusing on the benefits it offers in the production of custom parts like boat doors, hulls, and other essential components.

Why Fiberglass and RTM Are Ideal for Marine Applications

Fiberglass is the material of choice in the marine industry due to its excellent balance of strength, weight, and corrosion resistance. When combined with the RTM process, fiberglass components gain even more advantages, including enhanced durability, precision, and surface finish. These properties are crucial for marine environments, where exposure to water, salt, and UV radiation can take a toll on materials.

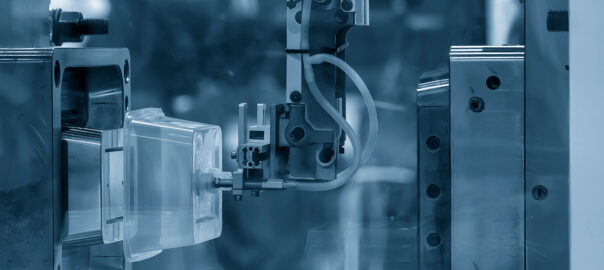

RTM and Marine Durability: The RTM process involves injecting resin into a mold containing a fiber reinforcement, such as fiberglass. This method ensures that the resin fully impregnates the fibers, creating a strong bond that enhances the durability of the final product. For marine applications, this means components that can withstand the rigors of the sea, from constant water exposure to impact from waves and debris.

Custom Fiberglass Parts for Marine Vessels

Boat Hulls: One of the most critical components of a marine vessel is its hull. The hull must be strong enough to endure the stress of navigating through water while remaining lightweight for optimal performance. RTM is particularly well-suited for manufacturing boat hulls because it allows for precise control over the thickness and fiber orientation, resulting in a hull that is both strong and lightweight. Additionally, the smooth finish achieved through Resin Transfer Molding enhances hydrodynamics, contributing to better fuel efficiency and speed.

Boat Doors and Hatches: Marine doors and hatches must be robust to ensure the safety and security of the vessel, yet they also need to be lightweight and resistant to corrosion. RTM offers the perfect solution by producing fiberglass doors and hatches that meet these requirements. The ability to mold complex shapes with integrated features, such as seals and hinges, makes Resin Transfer Molding an ideal choice for manufacturing these components. Furthermore, the enhanced surface finish achieved through RTM improves the aesthetic appeal and functionality of these parts.

Other Marine Components: Beyond hulls and doors, RTM is used to produce a wide range of other fiberglass components for marine vessels. These include interior panels, bulkheads, consoles, and even decorative elements. The versatility of RTM allows manufacturers to produce parts that are not only functional but also aesthetically pleasing, which is important for both commercial and recreational vessels.

Water Resistance and Environmental Factors

One of the most significant challenges in the marine industry is protecting materials from water and environmental degradation. Fiberglass components produced through RTM are highly resistant to water absorption, which prevents swelling, warping, and degradation over time. This water resistance is further enhanced by the use of high-quality resins specifically formulated for marine applications. These resins offer excellent resistance to UV radiation, saltwater, and chemicals, ensuring the longevity of the fiberglass parts.

In addition to water resistance, RTM allows for the incorporation of gel coats and other surface treatments that provide an additional layer of protection against the harsh marine environment. These coatings can also improve the appearance of the parts, providing a smooth, glossy finish that is both attractive and easy to maintain.

Sustainability and Cost-Effectiveness

As the marine industry moves toward more sustainable practices, RTM offers a cost-effective solution that minimizes waste and optimizes material usage. The closed-mold nature of the RTM process reduces emissions and allows for better control over material distribution, resulting in less waste and a more environmentally friendly production process.

Additionally, the durability of RTM-produced fiberglass parts means that they require less frequent replacement, reducing the overall environmental impact and lifecycle costs. This sustainability aspect is increasingly important as the marine industry seeks to balance performance with environmental responsibility.

Conclusion

Resin Transfer Molding is revolutionizing the production of custom fiberglass parts for the marine industry. With its ability to produce strong, lightweight, and water-resistant components, RTM is ideally suited for manufacturing critical marine parts such as boat hulls, doors, and hatches. As the demand for high-performance, durable, and sustainable marine components continues to grow, RTM stands out as the process of choice for manufacturers looking to meet the stringent demands of the marine environment.