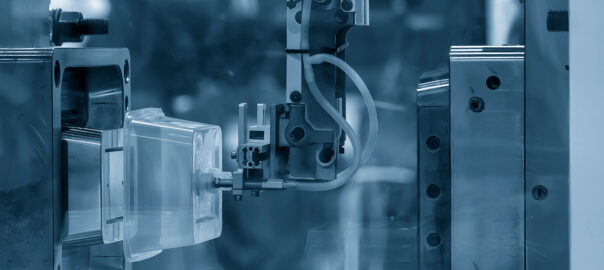

Michigan is home to numerous high-quality injection molding companies that serve a wide range of industries, from automotive and medical to consumer goods. Below is a list of the top 10 injection molding companies in Michigan, highlighting their key services, certifications, and industry expertise.

1. MMI Engineered Solutions

Location: Saline, MI

Key Benefits:

-

Specializes in custom injection molding and engineered solutions.

-

ISO 9001 and IATF 16949 certified, ensuring adherence to high-quality manufacturing standards.

-

Serves industries such as automotive, heavy truck, and industrial.

-

Offers services from product development to full-scale production.

Pros:

-

Strong focus on the automotive industry.

-

Advanced engineering support.

-

Certified to high industry standards.

Cons:

-

Primarily serves larger-scale production.

2. Jimdi Plastics (Contact Us)

Location: Allendale, MI

Key Benefits:

-

Specializes in custom injection molding with a focus on small-to-mid-size production runs.

-

ISO 9001 certified, ensuring consistent quality control across all manufacturing processes.

-

Serves industries such as automotive, consumer products, and electronics.

-

Known for flexible services, personalized customer interaction, and competitive pricing.

Pros:

-

ISO certified, ensuring high-quality production standards.

-

Flexible, ideal for low-to-medium volume production runs.

-

Excellent customer service with direct communication and adaptable solutions.

Cons:

-

Focused primarily on custom solutions, which may require slightly longer lead times due to the tailored nature of projects. This emphasis ensures high precision and attention to detail.

3. PTI Engineered Plastics

Location: Macomb, MI

Key Benefits:

-

Specializes in complex injection molding and plastic components.

-

ISO 13485 and ISO 9001 certified, with expertise in medical device manufacturing.

-

Provides design, tooling, and production services under one roof.

Pros:

-

Specializes in medical-grade plastics.

-

In-house design and development services.

-

High level of quality assurance and certifications.

Cons:

-

Primarily focuses on medical and highly regulated industries.

4. Medbio

Location: Clinton Charter Township, MI

Key Benefits:

-

Specializes in injection molding for medical and biotech industries.

-

ISO 13485 and ISO 9001 certified, focusing on producing medical devices and components.

-

Offers cleanroom molding for high-precision parts.

Pros:

-

Focuses on medical-grade components.

-

Advanced technology for cleanroom production.

-

High level of quality and regulatory compliance.

Cons:

-

Primarily serves medical and biotech sectors, limiting applicability for other industries.

5. Extreme Tool & Engineering (Now part of Westfall Technik)

Location: Wakefield, MI

Key Benefits:

-

Specializes in custom injection molding, design, and tooling services.

-

ISO 9001 certified, ensuring high standards in both design and production.

-

Now part of Westfall Technik, offering enhanced capabilities through expanded global resources and technology access.

Pros:

-

High expertise in complex tooling and part design.

-

Serves multiple industries, including automotive and electronics.

-

Access to additional resources and advanced technology through Westfall Technik.

Cons:

-

The transition into Westfall Technik brings opportunities for growth but may also lead to adjustments in customer interaction and processes as the company integrates into a larger network.

6. ADAC Automotive

Location: Grand Rapids, MI

Key Benefits:

-

Injection molding company specializing in automotive components.

-

ISO/TS 16949 certified, ensuring stringent automotive industry standards.

-

Offers design, tooling, and manufacturing for interior and exterior automotive parts.

Pros:

-

Expertise in automotive parts.

-

ISO/TS 16949 certified for the automotive industry.

-

Full-service design and manufacturing.

Cons:

-

Focused almost exclusively on the automotive sector.

7. Lacks Enterprises

Location: Grand Rapids, MI

Key Benefits:

-

Specializes in injection molding for automotive exterior components.

-

ISO/TS 16949 certified, focusing on producing high-quality automotive trims and finishes.

-

Provides chrome-plating and decorative finishes for molded parts.

Pros:

-

Specializes in automotive trim and exterior components.

-

Expertise in decorative finishing, such as chrome plating.

-

ISO certified for quality and safety.

Cons:

-

Exclusively serves the automotive industry.

8. West Michigan Plastics

Location: Holland, MI

Key Benefits:

-

Custom injection molding company offering a wide range of plastic components.

-

ISO 9001 certified, providing high-quality products for industries such as automotive, consumer goods, and industrial applications.

-

Specializes in both prototyping and full-scale production services.

Pros:

-

ISO certified for quality assurance.

-

Flexible in handling both small and large production volumes.

-

Strong industry experience, particularly in automotive and consumer products.

Cons:

-

Focused mainly on consumer goods and automotive industries, limiting specialized sectors.

9. Cascade Engineering

Location: Grand Rapids, MI

Key Benefits:

-

A leading plastic injection molding company offering custom solutions for industries such as automotive, industrial, and consumer products.

-

ISO 9001 and IATF 16949 certified, specializing in sustainable manufacturing.

-

Provides full-service solutions, from design to high-volume production.

Pros:

-

Sustainability-focused.

-

Expertise in large-scale, high-tonnage production.

-

Multiple certifications ensuring high-quality standards.

Cons:

-

Primarily focused on high-tonnage parts, which may limit flexibility for smaller projects or prototyping.

10. Summit Plastic Molding

Location: Shelby Township, MI

Key Benefits:

-

Specializes in injection molding services for automotive and consumer industries.

-

ISO 9001 certified, providing both low and high-volume production.

-

Offers value-added services like assembly, painting, and packaging.

Pros:

-

Flexible production capabilities.

-

Offers value-added services to enhance customer experience.

-

ISO certified.

Cons:

-

Primarily serves the automotive and consumer markets, limiting focus on other industries.

Conclusion

Michigan remains a leader in the injection molding industry, with a strong mix of companies serving a wide range of industries. Whether you’re looking for high-precision parts or large-scale production, these top 10 injection molders are excellent options. Jimdi Plastics stands out for its flexible services, competitive pricing, and ISO certification, making it a reliable choice for small-to-medium production runs in Michigan’s thriving manufacturing sector.